1. Compact the material. Improve the traditional mold design structure, and open a material-containing gap on the discharge plate (that is, when the mold is closed, the discharge plate is…

What to do when the stamping parts are turned over?

1. Compact the material. Improve the traditional mold design structure, and open a material-containing gap on the discharge plate (that is, when the mold is closed, the discharge plate is…

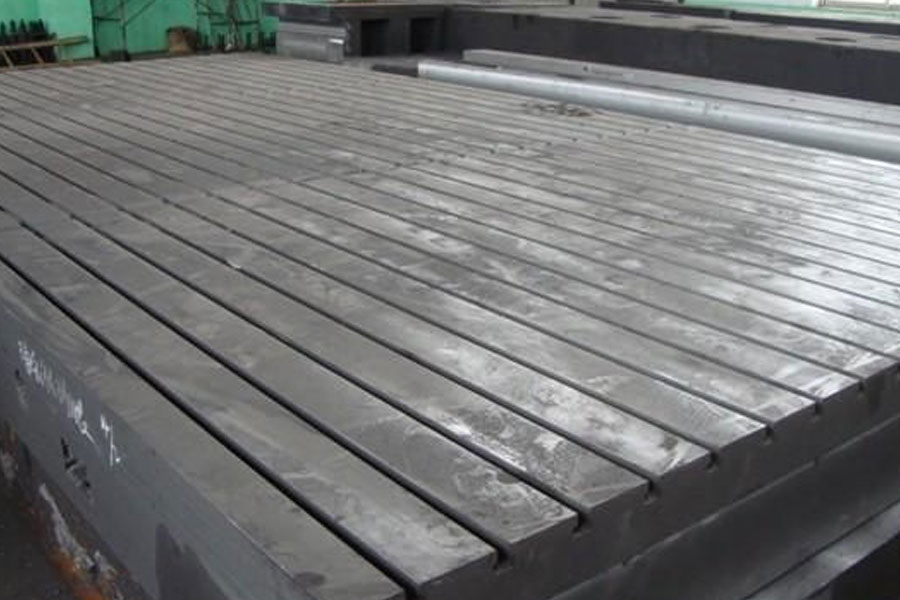

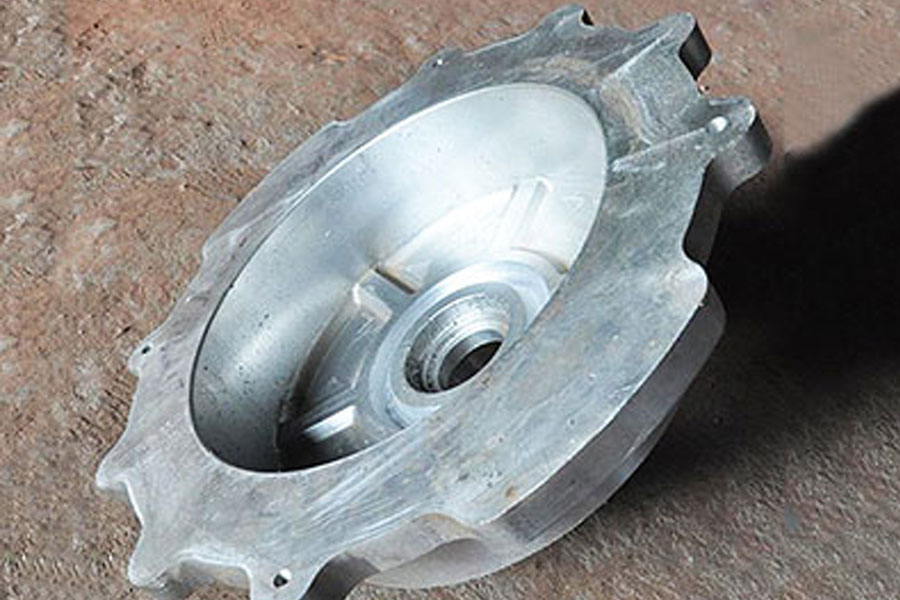

1. Hardware molds are used in industrial production to use various presses and special tools installed on the presses to make parts or products of the required shape from metal…

In life, hardware has been used in many places. With the development and progress of society, the application of hardware is also increasing. At present, many hardware products in China,…

1. The smoothness of drawing oil: This is the most important function of drawing oil. The smoothness is not good, and the workpiece will split, the plate and metal will…

1. Blanking: It is a process in hot stamping forming, punching out the required outer contour blank of the plate. 2. Austenitization: includes two stages of heating and holding. The…

1. It is caused by the burrs of the punching parts produced during blanking. Need to study the cutting edge, and pay attention to check whether the blanking is reasonable.…

Metal Stamping processing is mainly processed by classification, which can be divided into independent processes and constituent processes into two categories. The separation process, also known as stamping, is to…

Precision Metal Stamping is a kind of high-precision stamping processing. The stamping parts produced by this processing have high precision, good quality and good appearance. However, this requires good processing…

There is a process in the stamping process called stretch forming, this process is one of the main processes of stamping process, all Metal Stamping processes will use this stretch…

1. During the use of Metal Stamping dies, punch breakage, twists, and gnawing will occur. Punch sleeves are usually gnawed, and the damage of punches and sleeves is generally replaced…