1. In the daily processing of Metal Stamping parts, the punching size is too large or small, and the size of the punch is quite different. 2. When the punching…

Common problems in the processing of metal stamping parts

1. In the daily processing of Metal Stamping parts, the punching size is too large or small, and the size of the punch is quite different. 2. When the punching…

Upper die seat: The uppermost die seat is usually directly contacted on the punch frame die. Generally speaking, it is larger than the lower module. According to the principle of…

The hole measurement of Metal Stamping parts takes the minimum value according to the measurement method of the stop gauge, so when you use the caliper to record the measurement,…

Importance of tensile mold materials: When the customer's requirements for materials are not very strict and repeated mold tests cannot meet the requirements, you can try again with materials with…

The determination of the stamping die process plan is the most important link that should be carried out after the processability analysis of stamping parts. It includes process analysis according…

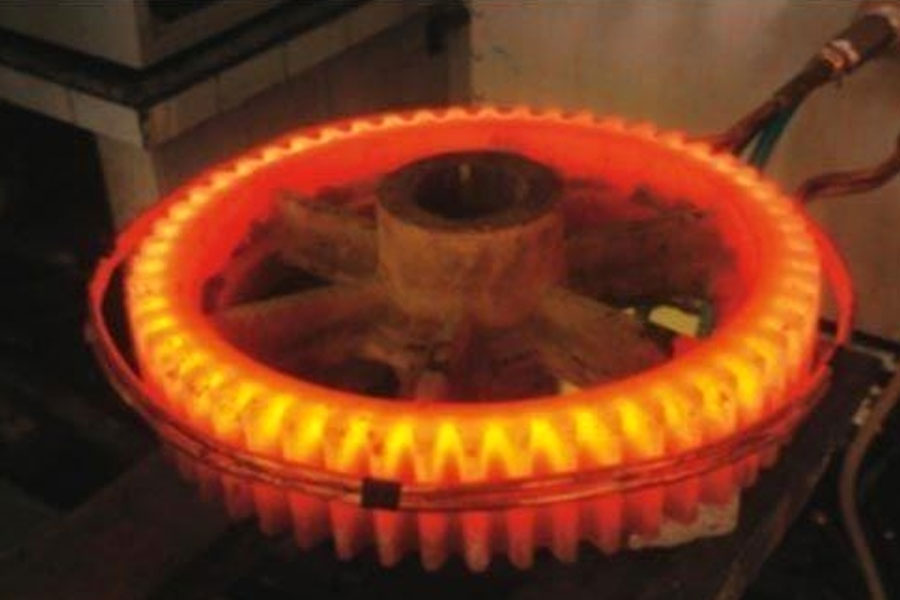

1. Strength and toughness: Most of the working conditions of the mold are very bad, and some of them are often subjected to a large impact load, which causes brittle…

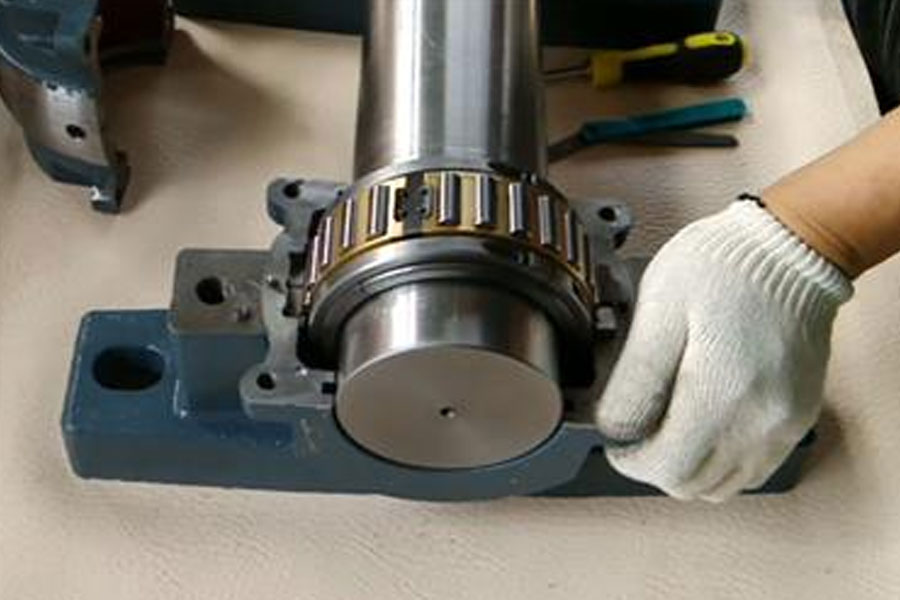

1. Put the mold handle into the upper mold base for later use; 2, put the punch into the fixed plate, and insert the punch into the fixed plate into…

1. Punching and shearing die: the work is done by shearing. Commonly used forms are shearing die, blanking die, punching die, trimming die, edge die, punching die and punching die.…

1. Check whether there are foreign objects in the card slot The mold insert will sink after a long time of use. Once you find this phenomenon, you have to…

The tensile properties of metal materials depend on the characteristics of the material (such as chemical composition, organizational structure, etc.), but the results obtained in different tensile experiments for the…