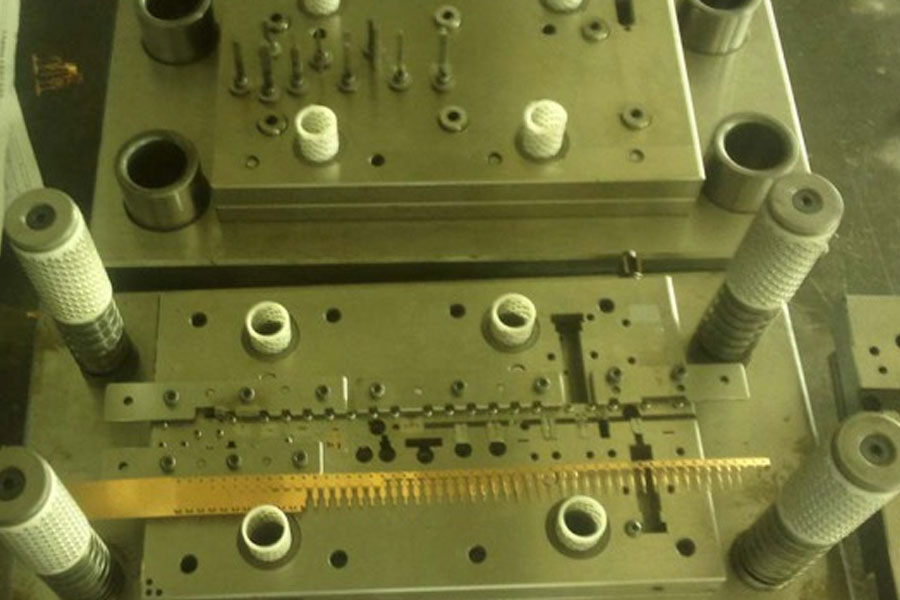

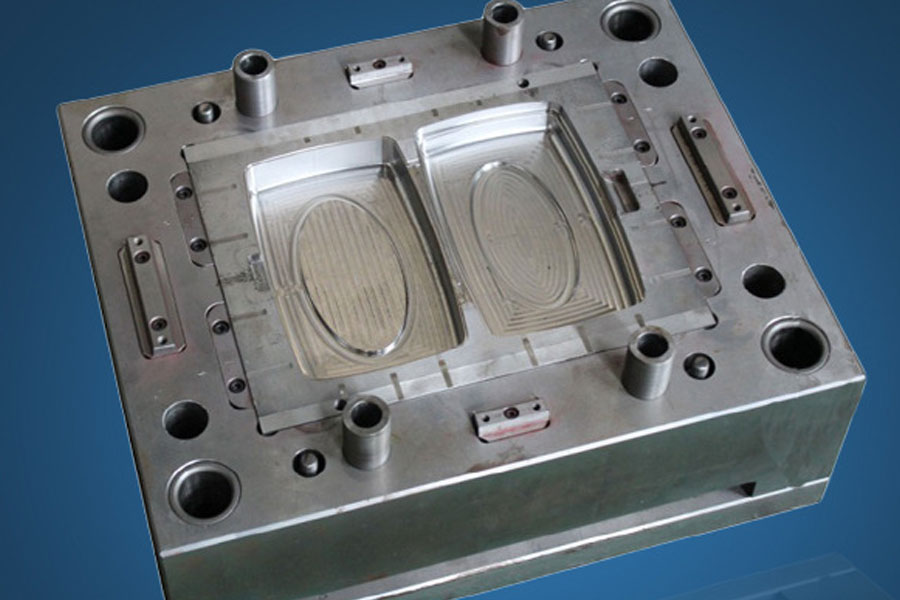

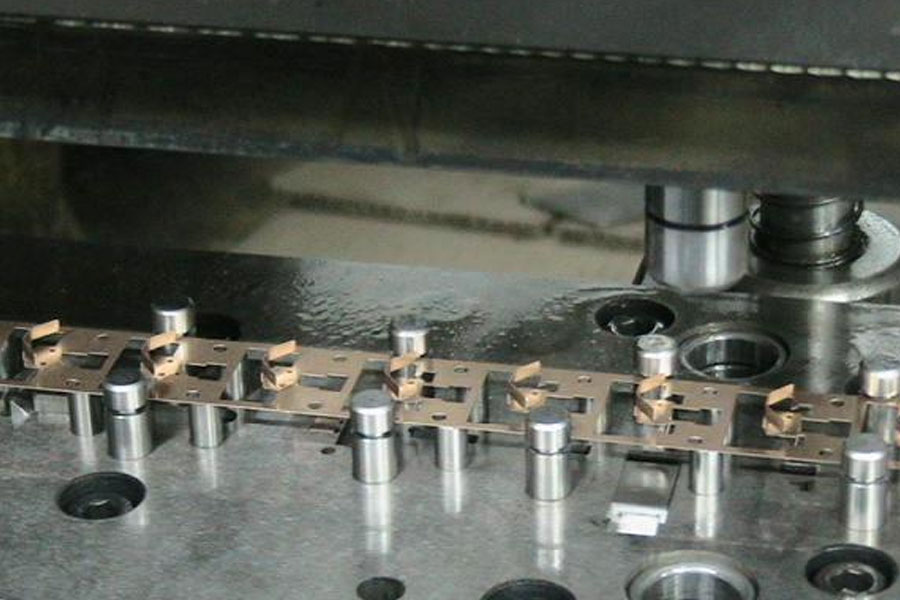

Inspection method: visual inspection, whetstone polishing, touch, oiling Inspection standards: Class A defects: Users who have not been trained in stamping parts Ⅰ and Ⅱ can also notice this type…

Inspection method for wave appearance of stamping parts