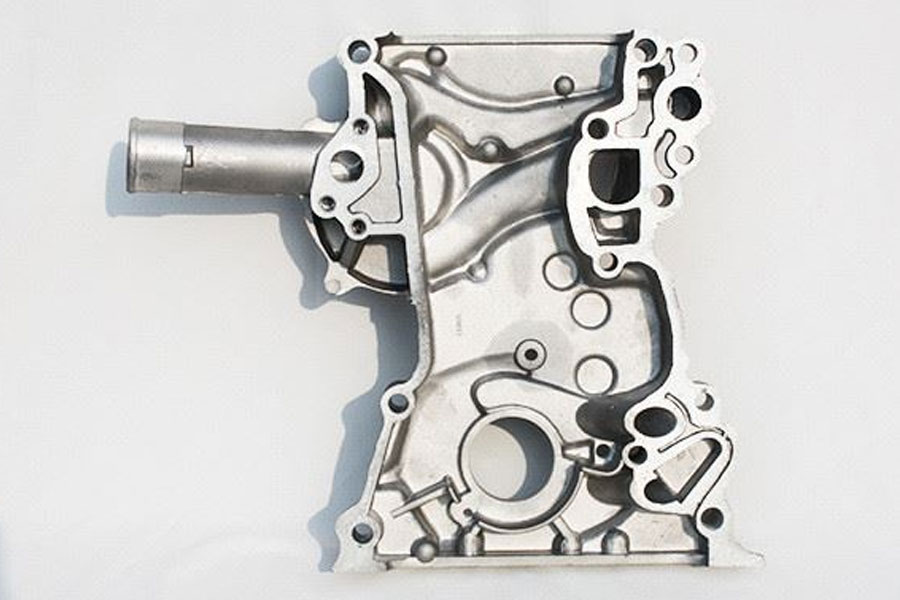

Valves are mainly used for the circulation and cut-off of pipeline media such as water, steam, gas and oil, flow and pressure regulation, and change of flow direction, etc. Brass…

Red Punching Process and Die Design of Brass Gate Valve Body

Valves are mainly used for the circulation and cut-off of pipeline media such as water, steam, gas and oil, flow and pressure regulation, and change of flow direction, etc. Brass…

The most common materials we use in stamping are copper, pure copper, brass and bronze.The stamping process of pure copper, H62 brass and H68 brass is better in stamping. In…

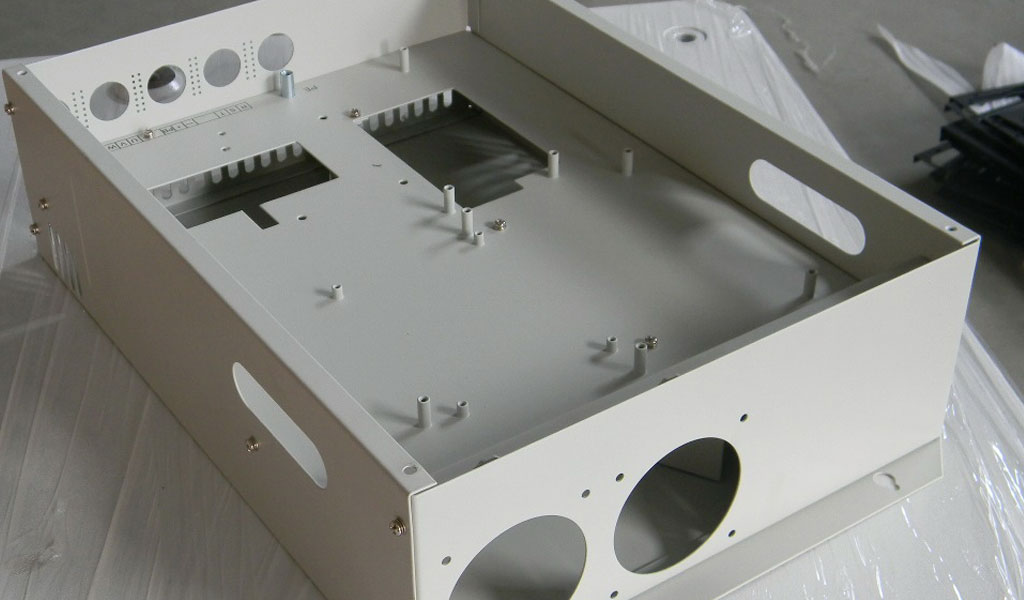

Sheet metal chassis processing structure is a common form of military airborne communication equipment chassis. Its structure is simple, regular, symmetrical, light in weight, and has the advantages of low…

FABLE SHC series synthetic gear oil is blended with high-quality synthetic hydrocarbon base oil and selected additives, suitable for lubricating the relationship between bearings and gears under severe working conditions.…

1. Determined according to the stamped product: 1. The material of the product must be made of metal before high-speed punching can be carried out. 2. The thickness and width…

1. High material utilization. Through different layout methods, such as: cross, diagonal, multi-row, mixed, nested, and even no waste layout, flat stamping parts can effectively improve the utilization rate of…

Product quality analysis of stamping die drawing parts During the product drawing process, the drawing parts will mainly have these kinds of problems: wrinkling, cracking, uneven thickness, surface scratches, shape…

1. For stamping parts with holes or gaps, when selecting a single-process die, the stamping parts processing plant usually blanks the material first and then punches or gaps. When selecting…

1. Oiling inspection Wipe clean the surface of the outer cover with clean gauze. Then use a clean brush to apply oil evenly to the entire surface of the stamping…

1. Derusting the bottom layer of sheet metal processing products 2. For sheet metal processing products, epoxy zinc-rich primer is mainly used for anti-rust primer of steel structure and steel…