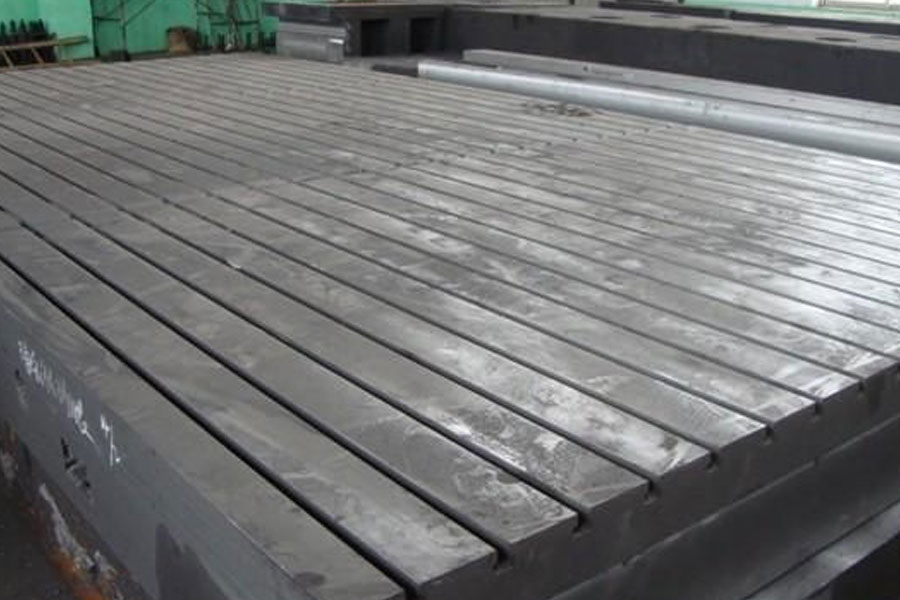

1. Hardware molds are used in industrial production to use various presses and special tools installed on the presses to make parts or products of the required shape from metal materials through pressure. These special tools are collectively referred to as hardware molds.

2. Plastic mold is a combined plastic mold for compression molding, extrusion molding, injection, blow molding and low foam molding. It mainly includes a concave mold with a variable cavity composed of a female mold combined substrate, a female mold component and a female mold combined card board, and a convex mold combined substrate, a male mold component, a male mold combined card board, and a cavity cutting component A punch with a variable core composed of a side-cut composite board. Coordinated changes of mold convex, concave mold and auxiliary molding system. Series of plastic parts of different shapes and sizes can be processed.

3. The most essential difference between them is that the hardware products are produced in the hardware mold, and the plastic products are produced in the plastic mold, and the structure of the mold is different. The plastic mold has a cooling system, but the hardware mold does not. The molding principle of the product is also different. The plastic mold is formed by cooling after injection, and the metal mold is formed by cold backlogging of standard thickness steel plates.

4. From the perspective of the function of the mold, the hardware mold is a mass production tool for metal products. The materials he uses are generally iron, copper or aluminum. The plastic mold is for plastic products, and the raw materials used are also plastic raw materials.

Leave a Reply