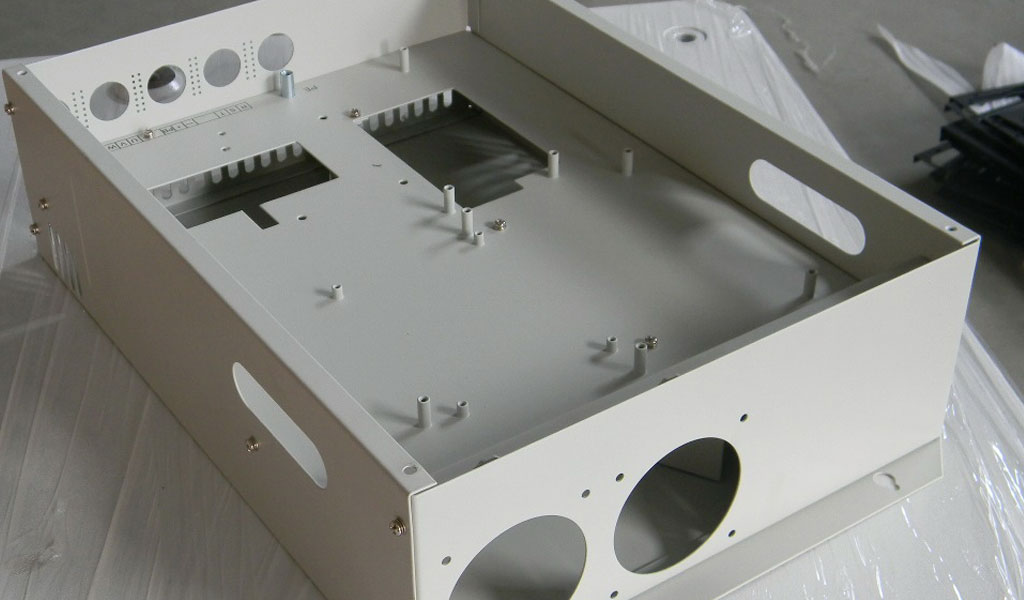

Sheet metal chassis processing structure is a common form of military airborne communication equipment chassis. Its structure is simple, regular, symmetrical, light in weight, and has the advantages of low cost and easy processing.

The whole chassis of the sheet metal structure is assembled from bent parts, which has good rigidity and strength. The following points should be paid attention to when manufacturing the sheet metal chassis cabinet structure:

- The material is anti-rust aluminum with good plasticity, and the thickness of the chassis material is consistent.

- If the radius of the inner edge of the bend is too small, it will cause cracking, and if it is too large, it will cause rebound. The process requirements should be taken as the design basis, the inner diameter of the bending should be reasonably designed, and the existing bending dies should be used for processing.

- Consider the manufacturability of the mechanical processing of sheet metal parts, such as the single-side bending height should not be too small, there must be a safe distance between the punching and blanking, and the margins of the bending and punching are reasonable.

- After the sheet metal is bent, the dimensional tolerance based on the bending edge should be set to 0.3mm, which is more economical. The accuracy of the chassis shape, hole position and other dimensions should be reasonably designed to avoid excessive tolerance and increase unnecessary costs.

Design points of military sheet metal structure chassis: The chassis is the basis for realizing the technical requirements of equipment, and is usually the main object of structural design. Communication equipment is usually an independent shell-type chassis, which can be subdivided into sheet metal chassis, milling chassis, welding chassis, modular aluminum chassis, etc. according to the structural form. Unless otherwise specified, the chassis size and accessories of military airborne electronic equipment shall comply with the provisions of GJB 441 and GJB 780.

Military airborne communication equipment is usually placed in the aircraft cabin. According to the requirements of GJB 376A, the appearance of the chassis is black (matte). The appearance of the equipment and the internal modules should be marked, and the nameplate should be installed in an obvious position of the equipment, with clear and durable content. Unless otherwise specified, no self-adhesive is used as the equipment nameplate. The structural design of the sheet metal chassis should fully consider the requirements of “three modernizations”, adopt a modular design, maximize the unified thread specifications, and use standard and common parts as much as possible. The chassis of airborne equipment requires miniaturization and lightweight design, and weight reduction measures must be adopted in the design stage of the structural scheme.

In order to meet the safety requirements of the chassis, the appearance of the chassis should not have sharp edges and corners, the discontinuity of the casing (covers, windows, etc.) should be as little as possible, and the exposed components (connectors, etc.) When the front panel is placed downwards, it can protect the protruding components on the panel. The externally installed sockets for discontinuous use should be equipped with protective covers. To effectively prevent loosening, the chassis should also have leakage protection measures.

Leave a Reply