Metal Stamping parts are processed in a variety of steel plate specifications, whether it is coiled or fixed-length version, the same material, material thickness, and different coil widths, the sales price will be very different. Therefore, in order to reduce costs, it is necessary to adopt methods from the formulation of the procurement roll width, and try to choose a roll width without price increase under the premise of material utilization.

For example, for cut-to-length plates, try to choose the appropriate size. After cutting from the steel mill, no secondary shearing is necessary, which greatly reduces the cost of cutting; for coiled plates, it is best to choose uncoiled coil specifications And technology, reduce the workload of secondary shearing, so as to improve work efficiency.

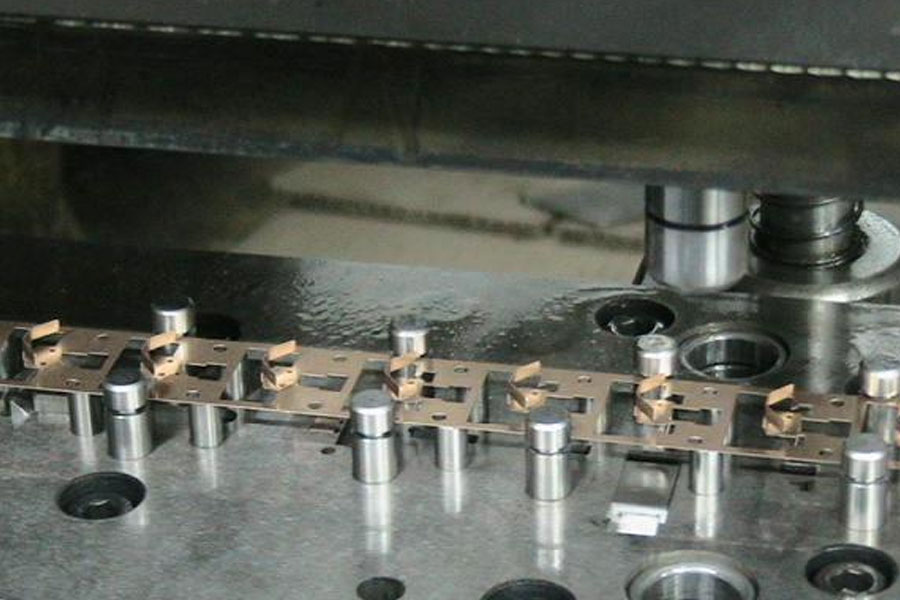

The processing of metal stamping parts is the production technology of using the power of conventional or special stamping equipment to directly subject the sheet metal to the deformation force and deform in the mold, so as to obtain product parts with a certain shape, size and performance. Sheet materials, molds and equipment are the three elements of stamping processing. Stamping is a method of metal cold deformation processing. Therefore, it is called cold stamping or sheet metal stamping, or stamping for short. It is one of the main methods of metal plastic processing (or pressure processing), and it also belongs to material forming engineering technology. Compared with castings and forgings, metal stamping parts have the characteristics of thinness, uniformity, lightness and strength.

Leave a Reply