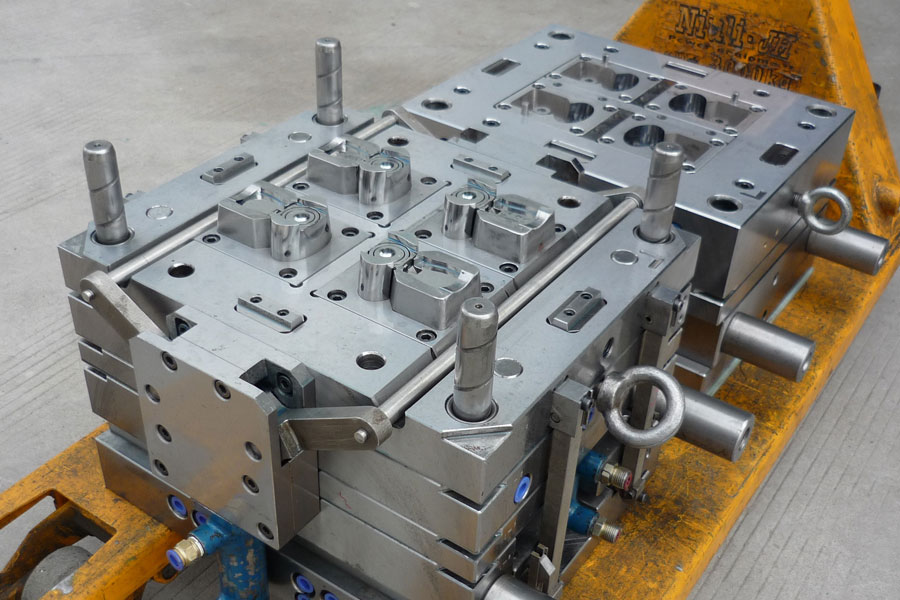

1. What is the clearance between the guide post and the guide sleeve, whether there are burns or wear marks, and whether the oil supply state of the mold guide…

Introduction of mold guide part inspection

1. What is the clearance between the guide post and the guide sleeve, whether there are burns or wear marks, and whether the oil supply state of the mold guide…

1. Reform the processing technology, molds and operating methods of Metal Stamping parts to realize manual work outside the mold. For mass production operations, we can start with reforming the…

Die is the main process equipment of stamping parts processing manufacturers. The surface quality, dimensional tolerances, productivity and economic benefits of stamping parts have a great relationship with the mold…

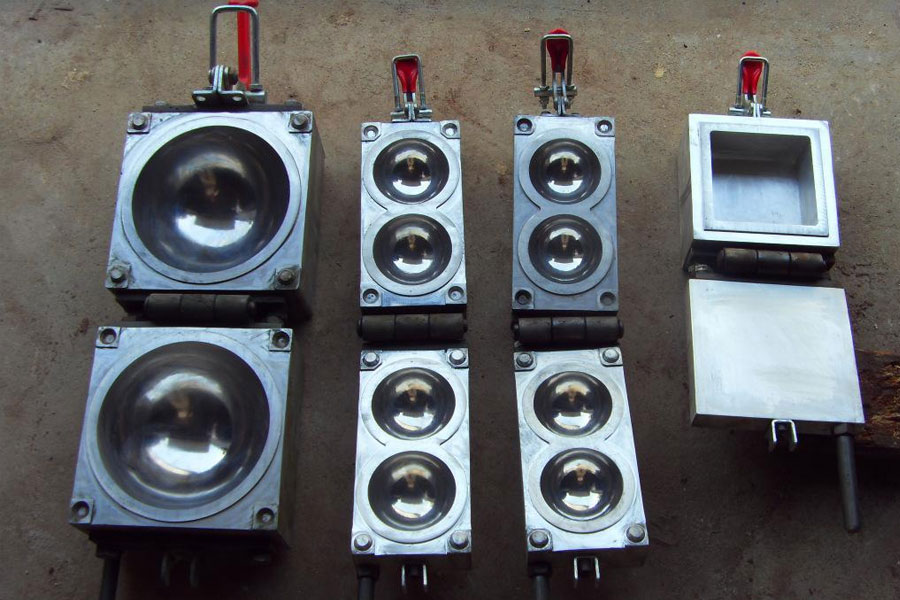

1. Prepare for heat treatment. The purpose of preheat treatment is to improve the cutting performance of the trend, eliminate the residual stress in the blank manufacturing era of CNC…

1. When processing products. The operator should maintain the correct posture and have enough energy to cope with the work. If you find that you are unwell, you must leave…

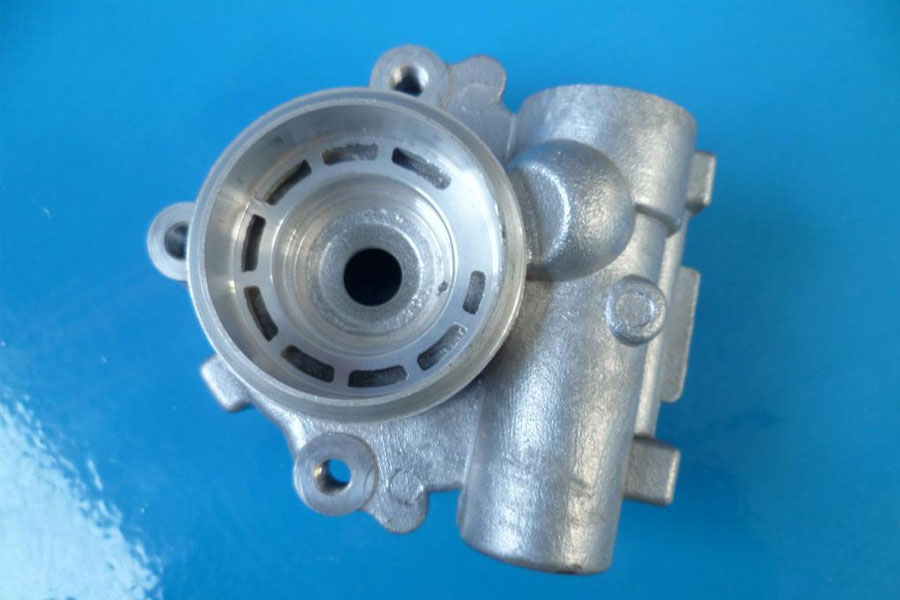

Non-standard parts processing refers to mechanical equipment that is not manufactured according to uniform standards in terms of type, specifications, performance, dimensions, drawings, tolerances and fits, technical document numbers and…

1. Civilized production: More than 30% of gear transmission noise is caused by burrs and bumps. Some precision machinery parts processing plants remove burrs and bumps before the gearbox is…

(1) There is no one to study the stamping parts market seriously, and the stamping parts market is chaotic. (2) The market competition in the home appliance and electrical appliance…

1. Easy to operate, reduce walking back and forth, and avoid unnecessary bending and tiptoe movements. 2. The positioning is accurate and reliable to prevent malfunctions due to slight vibration.…

The first stage: the elastic deformation stage When the cutting edge starts to contact the material, the material produces compression, stretching and bending deformation. The larger the cutting edge gap,…