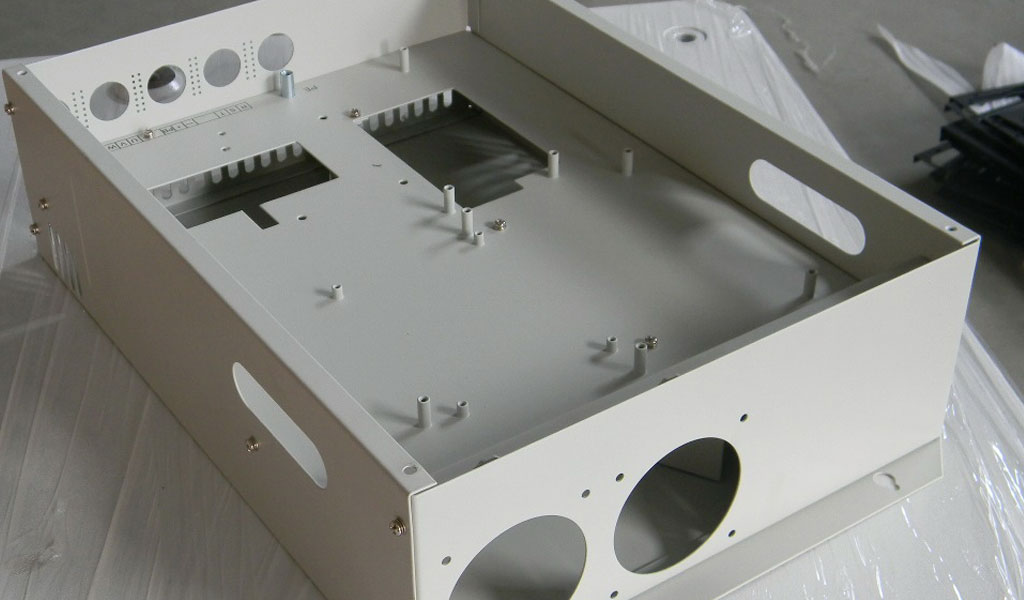

Sheet metal chassis processing structure is a common form of military airborne communication equipment chassis. Its structure is simple, regular, symmetrical, light in weight, and has the advantages of low…

Key Points of Military Sheet Metal Structure Chassis Design