(1) The pretreatment is not thorough. There is an oxide film on the surface of the workpiece, which affects the normal deposition of zinc. (2) Poor conductivity. The current is…

Points to pay attention to when stamping parts are galvanized

(1) The pretreatment is not thorough. There is an oxide film on the surface of the workpiece, which affects the normal deposition of zinc. (2) Poor conductivity. The current is…

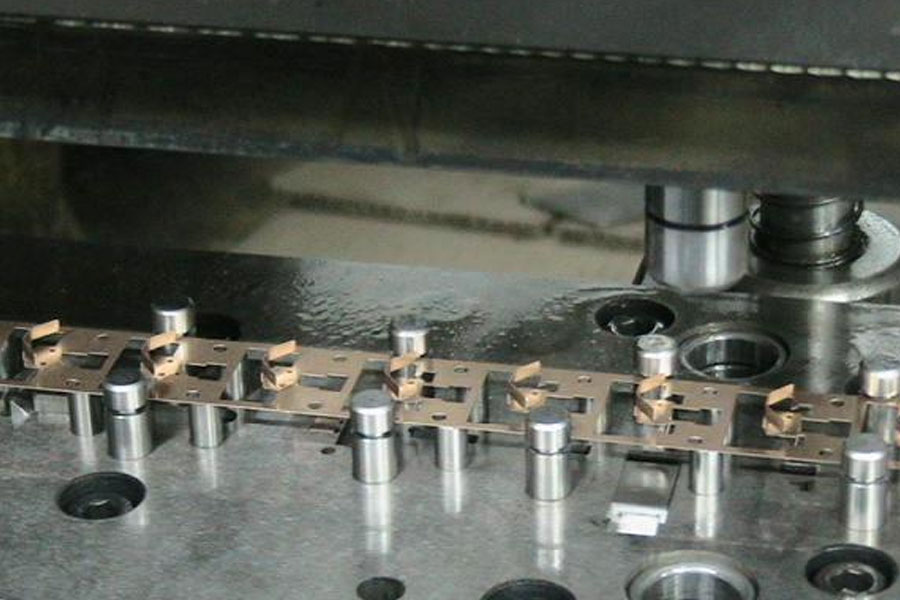

The advantage is: 1. Due to the single-piece processing and assembly technology, the production cycle is shorter; 2. Because the parts are spliced, local damage will not affect the overall…

Sheet metal processing is simple and convenient to use, and the investment cost is low. It has its own unique advantages in the processing of various sheet metal parts, especially…

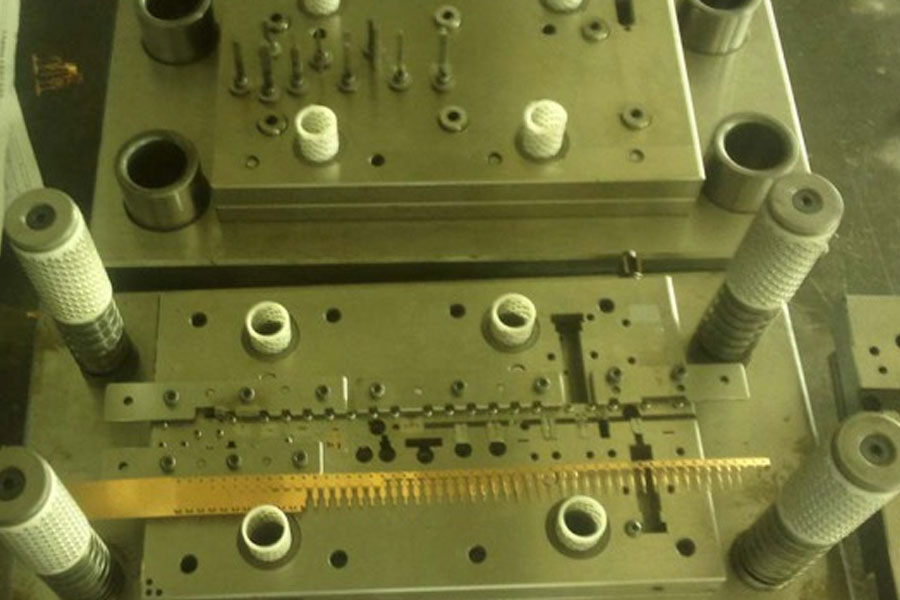

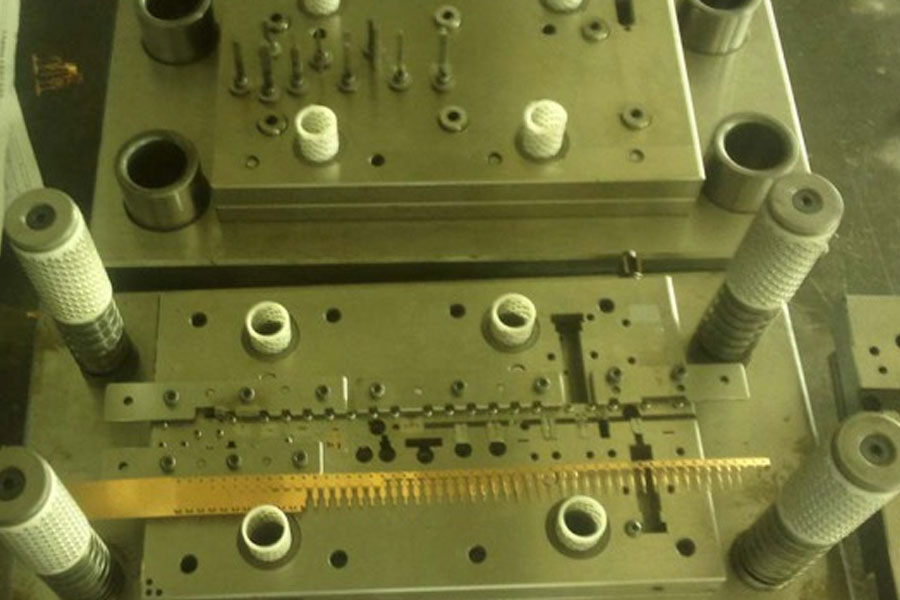

1. Number of punches Control of the raw materials received in the warehouse before counting: ①Whether the thickness of the raw materials used in various spare parts is consistent with…

The sheet metal processing production process refers to the entire process of making products from raw materials (or semi-finished products). For machine production, it includes the transportation and storage of…

1. Features: It depends on whether the chassis provides front USB and audio input and output ports. For example, the internal design of the hard disk, optical drive adopts rail…

Metal Stamping parts are processed in a variety of steel plate specifications, whether it is coiled or fixed-length version, the same material, material thickness, and different coil widths, the sales…

(1) Defects such as high yield point, high hardness, significant cold hardening effect, and cracks. (2) The thermal conductivity is worse than that of ordinary carbon steel, which results in…

1. The material used for blanking should have sufficient plasticity and low hardness to improve the quality of the blanking section and dimensional accuracy. Among them, soft materials (such as…

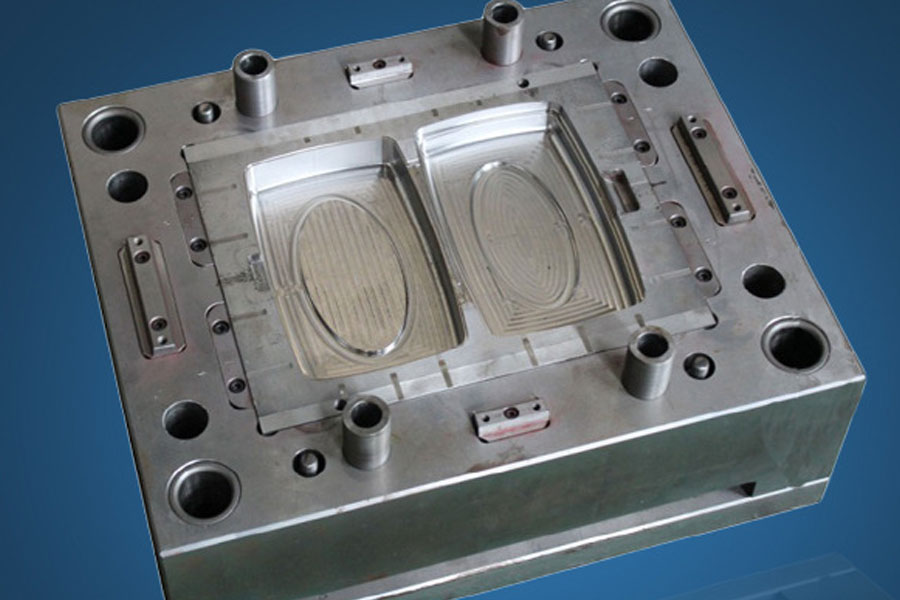

1. Material preparation: The mold materials required for different products are also different, and appropriate mold materials should be selected according to the characteristics of the product; 2. Rough processing:…