1. When performing continuous bending of soft materials such as copper and aluminum alloys, metal particles or scum are easy to attach to the surface of the working part, causing…

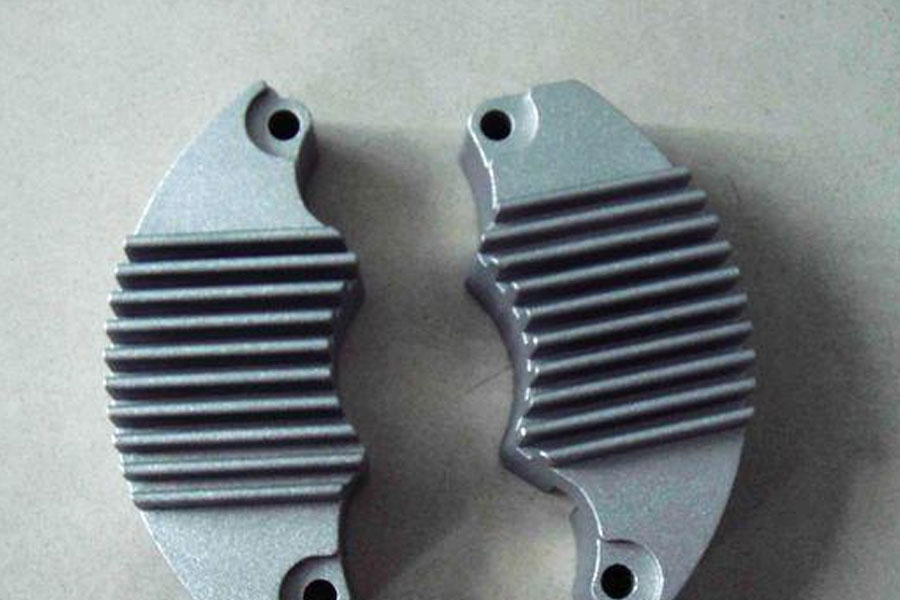

Causes of surface scratches on metal stamping parts

1. When performing continuous bending of soft materials such as copper and aluminum alloys, metal particles or scum are easy to attach to the surface of the working part, causing…

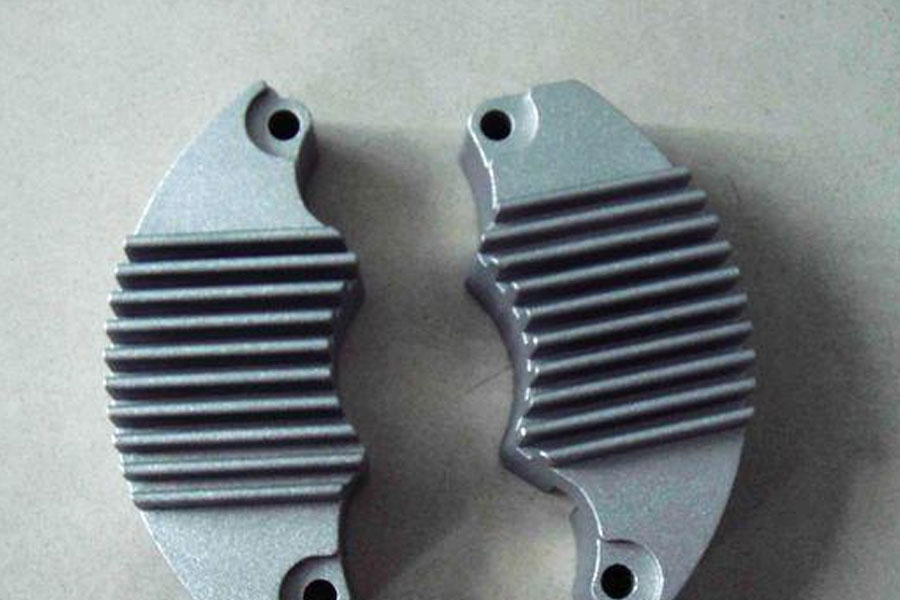

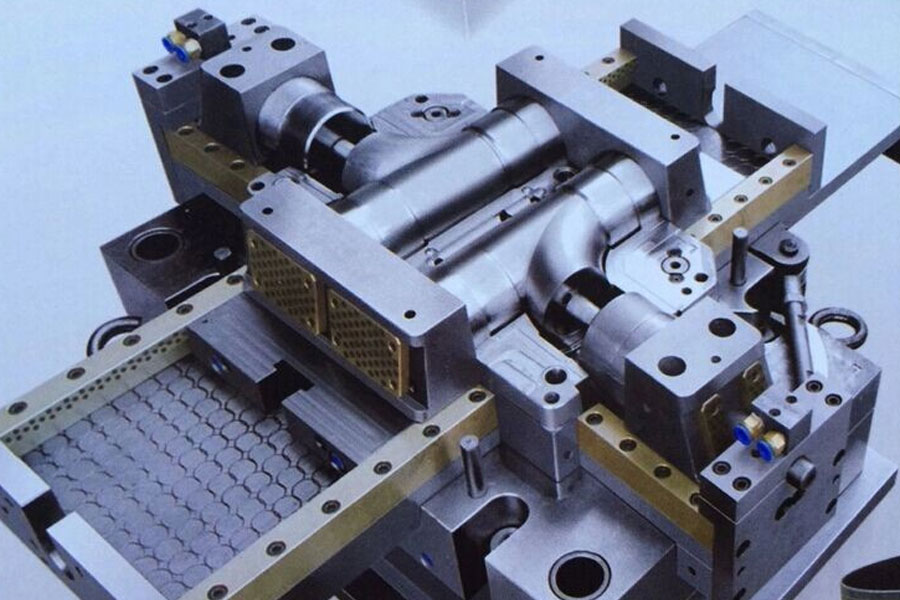

1. Fair selection of materials. For precision and complex molds, micro-deformed mold steels with good materials (such as air-quenched steel) should be selected.The die steel with severe carbide segregation should…

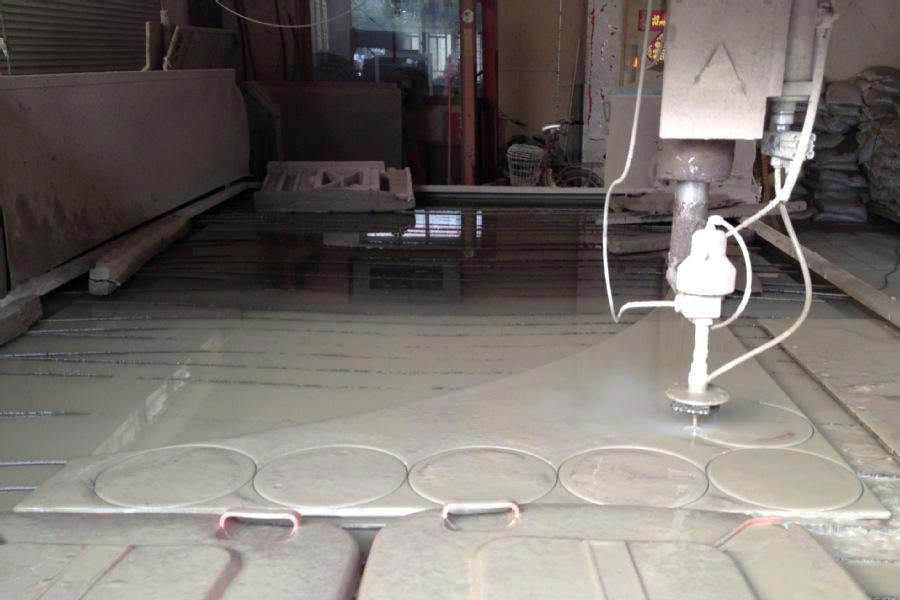

1. First consider the die set under "Selecting the stamping die", and analyze whether the straight line to be stamped is greater than or equal to 1.5 times the side…

Blanking, bending, stretching, different processes have different requirements for the plate, and the selection of materials should also consider the choice of the plate according to the general shape of…

1. The Metal Stamping parts are manufactured by stamping under the premise of low cost of materials. The parts are light in weight and rigid, and after the sheet material…

(1) The blanking die separates the material along the closed or open contour line. Such as blanking die, punching die, cutting die, slitting die, trimming die, cutting die, etc. (2)…

The successive mold is to place the stamping process (station) required for the finished product in the same set of molds for punching. The materials used for the successive molds…

When storing metal materials, clean and dry operations both inside and outside the warehouse, away from factories and workshops where harmful gases and dust are generated, and do not store…

1. Defects such as high yield point, high hardness, significant cold work hardening effect, and easy cracks; 2. In the processing of stainless steel stamping parts, the thermal conductivity is…

1. Using fully automatic stamping production line for stamping parts processing, the highest production cycle can reach 25 times per minute, so that the production efficiency has been significantly improved;…