1. The forming process parameters are not in place In the forming process of the part, the process requires that the die, the blanking core and the two must be…

Introduction to the tearing of stamping parts

1. The forming process parameters are not in place In the forming process of the part, the process requires that the die, the blanking core and the two must be…

1. Consider the die set under "Selecting the stamping die", analyze whether the straight line to be stamped is greater than or equal to 1.5 times the side length of…

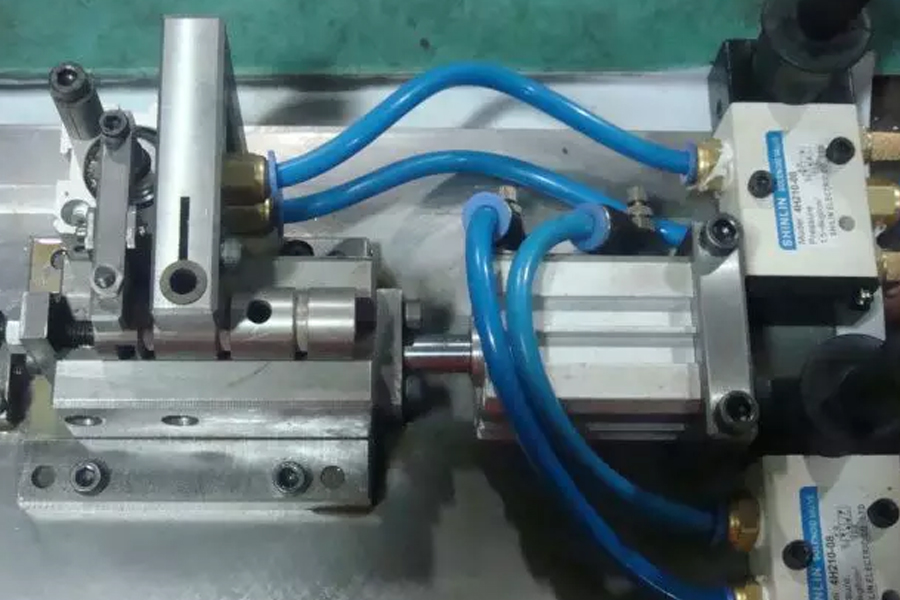

1. Continuous mold material belt function: The continuous mold is to arrange the stamping process (station) required to complete the product in the same set of molds for punching. The…

1: Aluminum profile cutting Aluminum profile cutting is the most basic and common processing method in aluminum profile CNC processing. Because the standard size of industrial aluminum profile is 6020mm,…

After the fiber laser cutting machine is used for a period of time, the cutting accuracy will have a certain error, which is often caused by the change of the…

stamping die is currently a widely used manufacturing method in the manufacturing industry, but the current level of stamping die production in my country is not ideal, and there is…

The use of physical vapor deposition technology in the surface treatment technology of mold materials prepares a titanium-containing compound strengthening layer with a thickness of about 3-5 μm on the…

With the development of my country’s industry, the application of precision stamping parts is becoming wider and larger, and the requirements for stamping technology are getting higher and higher.